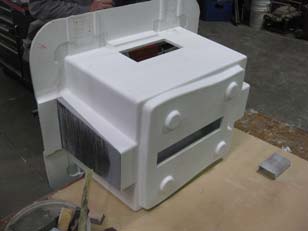

The Rotational Molding Process

Rotational molding, also known as rotomolding or rotocasting, is a small part of the plastics industry and the least known of the plastics processes in use today. Most Engineering courses only touch very briefly on the rotational molding process while focusing primarily on training new engineers to design for the Injection, Blow Molding, and Vacuum Forming processes. The rotational molding process however offers much in the way of design flexibility and scale of products, with products ranging from simple bulk storage containers to sophisticated automotive, medical, and aerospace applications. The concept of the rotational molding process was actually developed in the late 1800’s as a means to create artillery shells. The idea of rotational molding expanded in the early 1900’s for the processes of molding hollow chocolate’s and molding plaster of paris. It wasn’t until the 1950’s where plastics began being introduced to the process to create toys. Finally in the 1960’s, a low-density polyethylene was used to create large hollow containers. Polyethylene resins are now the most commonly used materials. Other options include Nylon’s, PVC, EVA, and Cross-Linked Polyethylene.

Rotational molding lends itself to hollow, complex forms like no other process. Small parts, such as medical pipette bulbs can be made in essentially the same manner as large boats. Intricate parts, such as fuel tanks and components for aircraft ducting are becoming more common as rotational molding is recognized by a broader group of designers and engineers. Products need to be specifically designed for manufacture from this unique process. Working directly with a Design Engineer trained in this process at the beginning of the product development phase will assure a smooth and successful transition of your products into the rotational molding process.

Previous Post

Previous Post